DZL链条蒸汽锅炉简介:

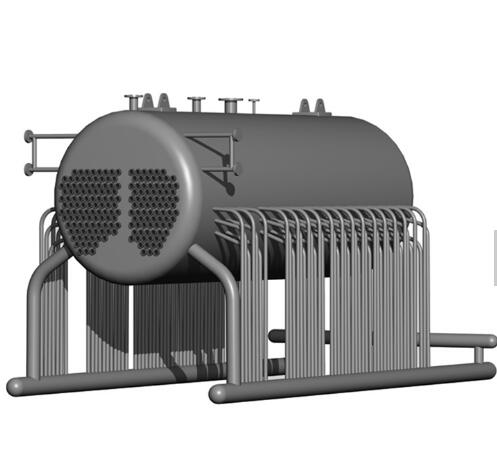

河南太锅锅炉生产的DZL 型锅炉是一种卧式三回程水火管式锅炉。在锅筒内布置二束火管,炉膛两侧装有光管水冷壁管;燃烧采用轻型链条炉排实现机械加煤,并配有鼓、引风机实现机械通 风。燃料自煤斗落到炉排上,随炉排进炉膛后燃烧,烟气经过后拱上部燃烧室,由燃烧室向上通过后棚管烟室进入第一管束到前烟箱,再由前烟箱折入第二束至后烟 箱,通过引风机抽引进入烟道、除尘器及烟囱,最后排向大气。该锅炉自动化水平高,锅炉给水自动调节、高低水位报警、低水位联锁保护,引、送风机联锁保护。 锅炉上煤、出渣等操作机械化,配套辅机齐全。

本产品具有成熟性、先进性、稳定性、可靠性、和经济性。

1、成熟性:国内最早生产燃煤快装螺纹管链条炉排锅炉的制造厂之一;自动化燃煤螺纹管链条炉排锅炉,填补国内燃煤螺纹管链条炉排蒸汽锅炉空白;十年来,产品多次更新换代,更趋成熟,同类产品已生产6000多台。

2、先进性:采用多项先进技术,如螺纹管、炉内强化燃烧; DZL燃煤锅炉多次荣获国家、机械工业部的产品荣誉证书;

3、稳定性:锅炉运行平稳,故障率低,未发生重大安全事故;早期锅炉最长运行时间已达10年。

4、可靠性:国内唯一一家对锅壳式锅炉进行过20万次疲劳试验的锅炉厂家;我公司为机械部定点的工业锅炉出口基地,燃油燃气锅炉已从2000年开始陆续出口巴基斯坦、孟加拉、缅甸、泰国、伊朗、阿尔及利亚、叙利亚、尼日利亚、哈萨克斯坦、利比亚、几内亚、印尼、也门、莫桑比克、越南、柬埔寨等17个国家和香港地区。

5、经济性:热效率高,节约燃料,经济性好;被国家经贸委和河南省环保局评为节能产品。

Introduction

DZL series coal&biomass fired stoker boiler is single drum, the combustion equipment is chain grate stoker. Water wall tubes at left and right sides of furnace are the radiated heating area. the two wings at furnace and screw fire tube in the drum are convection heating area. This coal fired stoker boiler uses the upper drum, water wall tube and head are in symmetrical arrangement mode. The drum is welded assembly by cylinder and front back tube plate. This furnace structure in reasonable arrangement and high efficiency. This stoker boiler adopts several environmental protect measures (bag dust collector, double towers desulfurization, etc.) to meet the national emission requirement.

This series coal fired stoker boiler uses the new scientific achievement, such as arch tube plate, screw fire tube to solve the problem of tube plate flaw, water wall tube explosion, low efficiency, insufficient output, poor adaptability of coal, improve the heat transfer.

Characteristics of Chain Grate Stoker

1) The small scale stoker could resist the temperature as high as 1200℃, long working life.

2) The stoker has a low coal leakage because of the small gap.

3) High automatic degree, decrease labor cost.

4) Convenient for maintenance, it could be repaired without boiler shut down.

Products Advantages

1. High Quality Assurance

1) There is a professional design engineer team, before manufacturing, every boiler design drawing have to be approved by boiler and pressure vessel experts of CSBTS ( State Bureau of Quality Technical Supervision ), and then the boiler could be produced only if qualified.

2) To ensure the raw materials quality, all the steel plates are special-used for boiler with the Inspection Certificates. The raw material materials are inspected when entering factory, and only the qualified material could be put in storage and used for production.

3) To ensure the welding quality, there a professional welding team, including more than 30 senior welders. The welding materials are stored under constant temperature and humidity, to ensure the welding material quality.

4) The welding quality will be further examined during boiler manufacturing, by using x-ray detection, ultrasonic flaw detection, magnetic test, or penetration test, etc.

5) To ensure the boiler quality, the leakproofness and strength of pressure parts will be tested. The hydrostatic test is done to make sure there are no water drop or water mist leakage appear on steal wall or welding joint, no water leakage appear at the place of expansion, and no obvious residual deformation and abnormal situation.

6) To ensure no problems before boiler delivery, all the raw materials and boilers are supervised and inspected by the experts of Inspection Institution for Boiler and Pressure Vessel. There are international uality certificates of ISO 9001 and CE, we can also offer the inspection report of SGS, BV, etc., Quality Certificates, Energy audit report, and Energy Efficiency Test Report, etc.